Design and production of vibrating resonant feeders

63kva Industrial Group is one of the manufacturer of Design and production of vibrating resonant feeders in Middle East

Resonance feeder 80 by 650 mm

Consumption of 50 watts Dbi up to one ton per hour with a suitable base for installation under KDC type tanks without the need for repairs and suitable for continuous work

type tanks without the need for repairs and suitable for continuous work

Resonance feeder with tube carrier

220 V 50W 1t/h (powder 0.5 kg/lit)

suitable for permanent work

Resonance sieve

resonance sieve dimensions 70 by 50 and 100 by 70 cm Consumption of 100 watts and tonnage of 7 tons per hour powder with a density of half a kilo per liter and mesh with 3 by 3 mm springsThe output tonnage depends on the size of the grid springs

resonance sieve dimensions 70 by 50 and 100 by 70 cm Consumption of 100 watts and tonnage of 7 tons per hour powder with a density of half a kilo per liter and mesh with 3 by 3 mm springsThe output tonnage depends on the size of the grid springs

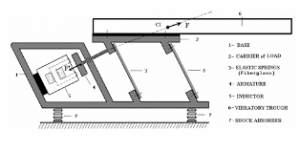

How does a vibrating feeder work?

Vibratory feeders utilize both vibration and gravity to move material forward. The force of gravity influences these parts to shift direction, causing them to move down or laterally. Simultaneously, vibration is employed to trigger the material’s movement.

How does an electromagnetic feeder work?

No matter the size, all these systems, including electromagnetic feeder, work on the same principle: they moves product by making the feeder vibrate. The pieces in the feeder, when it start to vibrate, move in a series of small hops. This series of hops create a flow, a constant motion of pieces.

principle: they moves product by making the feeder vibrate. The pieces in the feeder, when it start to vibrate, move in a series of small hops. This series of hops create a flow, a constant motion of pieces.